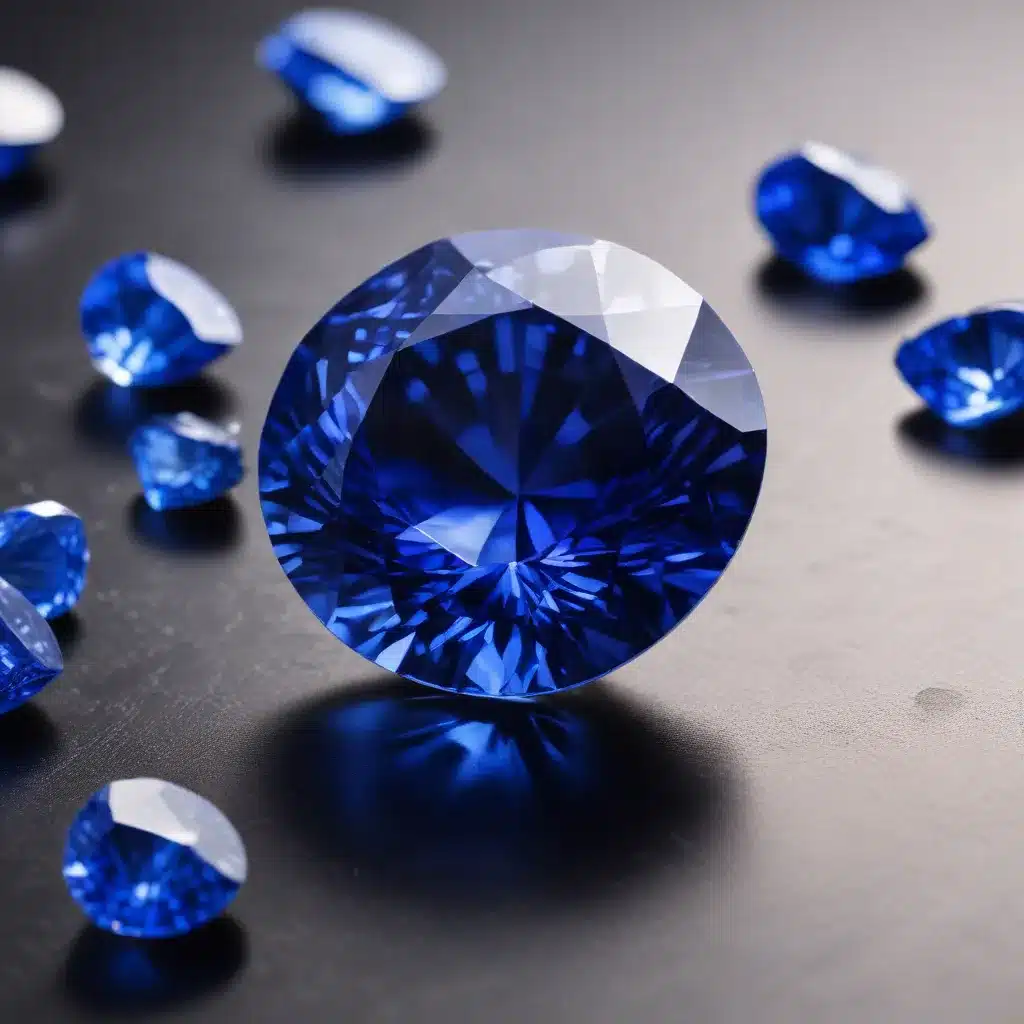

The realm of gemstones has long captivated the human imagination, with each precious stone carrying a unique allure and story. Among these gems, the revered sapphire stands out as a symbol of regal elegance and timeless beauty. While natural sapphires have been treasured for centuries, the advent of synthetic sapphire production has ushered in a new era of innovation and craftsmanship.

In the heart of the Shelby Gem Factory, we delve into the intricate processes that give birth to these captivating synthetic gems, exploring the cutting-edge techniques and the artistic mastery that transform raw materials into dazzling masterpieces.

Sapphire Formation Processes

The creation of synthetic sapphire is a testament to the remarkable advancements in materials science and crystallography. At the forefront of this innovation is the Czochralski Crystal Growth method, a process that involves slowly pulling a single crystal from a melt of aluminum oxide (corundum) and carefully controlling the temperature and atmosphere. This technique allows for the precise engineering of the crystal structure, ensuring the gem’s flawless clarity and consistent color.

Another prominent technique is the Flame Fusion (Verneuil) Process, where a flame is used to melt aluminum oxide powder, which then solidifies into a boule, or rough crystal. This method, while more cost-effective, can result in a slightly less uniform crystal structure when compared to the Czochralski method.

The Hydrothermal Synthesis approach, on the other hand, leverages high-pressure, high-temperature conditions to grow synthetic sapphire crystals from a mineralized solution. This process can produce gems with unique color variations and exceptional clarity, making it a preferred choice for specialty applications.

Synthetic Sapphire Properties

The allure of synthetic sapphire lies not only in its visual splendor but also in its remarkable physical properties. These lab-grown gems boast optical characteristics that rival their natural counterparts, with exceptional refractive index, dispersion, and luster. The ability to precisely control the growth conditions allows for the creation of flawless, eye-clean crystals, free from the inclusions and imperfections that can sometimes be found in natural sapphires.

In terms of hardness and durability, synthetic sapphire shines, ranking 9 on the Mohs Hardness Scale – just shy of the coveted diamond. This exceptional hardness, combined with its resistance to scratches, chips, and cracks, makes synthetic sapphire an ideal choice for high-wear applications, such as watch crystals and electronic device screens.

The versatility of synthetic sapphire extends to its colorization capabilities. While natural sapphires are primarily found in shades of blue, the controlled growth environment allows for the creation of a wide array of hues, from vibrant reds and oranges to lush greens and rich purples. This diversity of color options opens up endless design possibilities for the jewelry and fashion industries.

Technological Advancements in Sapphire Manufacturing

The production of synthetic sapphire is a highly specialized field, requiring precision engineering and innovative equipment. At Shelby Gem Factory, we stay at the forefront of these advancements, continuously optimizing our furnace design and atmospheric regulation to ensure the highest quality and consistency in our gems.

Automation and process monitoring play a crucial role in our operations. Robotic handling systems streamline the crystal growth and cutting processes, minimizing human error and maximizing efficiency. Our state-of-the-art computer-aided monitoring systems provide real-time data on temperature, pressure, and other critical parameters, enabling our expert technicians to make timely adjustments and maintain rigorous quality assurance protocols.

Through meticulous inspection, rigorous testing, and the latest defect identification techniques, we ensure that every synthetic sapphire produced at Shelby Gem Factory meets the exacting standards that have made our brand synonymous with excellence.

Applications of Synthetic Sapphire

The versatility of synthetic sapphire has made it a coveted material across a wide range of industries. In the realm of optoelectronics, these gems are prized as LED substrates and integral components in semiconductor devices, leveraging their exceptional optical properties and thermal conductivity.

In the world of luxury and fashion, synthetic sapphire has become a staple, adorning jewelry and accessories with its timeless beauty and unparalleled durability. The ability to produce large, flawless crystals has also made synthetic sapphire a sought-after choice for watchmaking, where its scratch-resistant properties are essential.

Beyond the realms of fashion and technology, synthetic sapphire has found applications in the industrial and military sectors. Its hardness and resistance to wear make it an ideal material for scratch-resistant coatings, while its optical transparency and impact resistance have led to its use in armor and ballistic protection applications.

The Art of Synthetic Sapphire Craftsmanship

The creation of a stunning synthetic sapphire is not merely a matter of technical prowess but also an intricate dance of artistry and precision. At Shelby Gem Factory, our master gem cutters and polishers employ a range of specialized techniques to bring out the full brilliance and beauty of these captivating gems.

From the delicate facet angles and meticulous surface finishing to the intricate patterns and color variations, each synthetic sapphire is a unique work of art, crafted with the utmost care and attention to detail. We harness the latest advancements in 3D printing and laser engraving to push the boundaries of what is possible, creating truly one-of-a-kind masterpieces.

As we continue to innovate and refine our processes, the world of synthetic sapphire remains a testament to the enduring allure of gemstones and the remarkable achievements of human ingenuity. At Shelby Gem Factory, we take great pride in being at the forefront of this captivating journey, cultivating perfection one gem at a time.