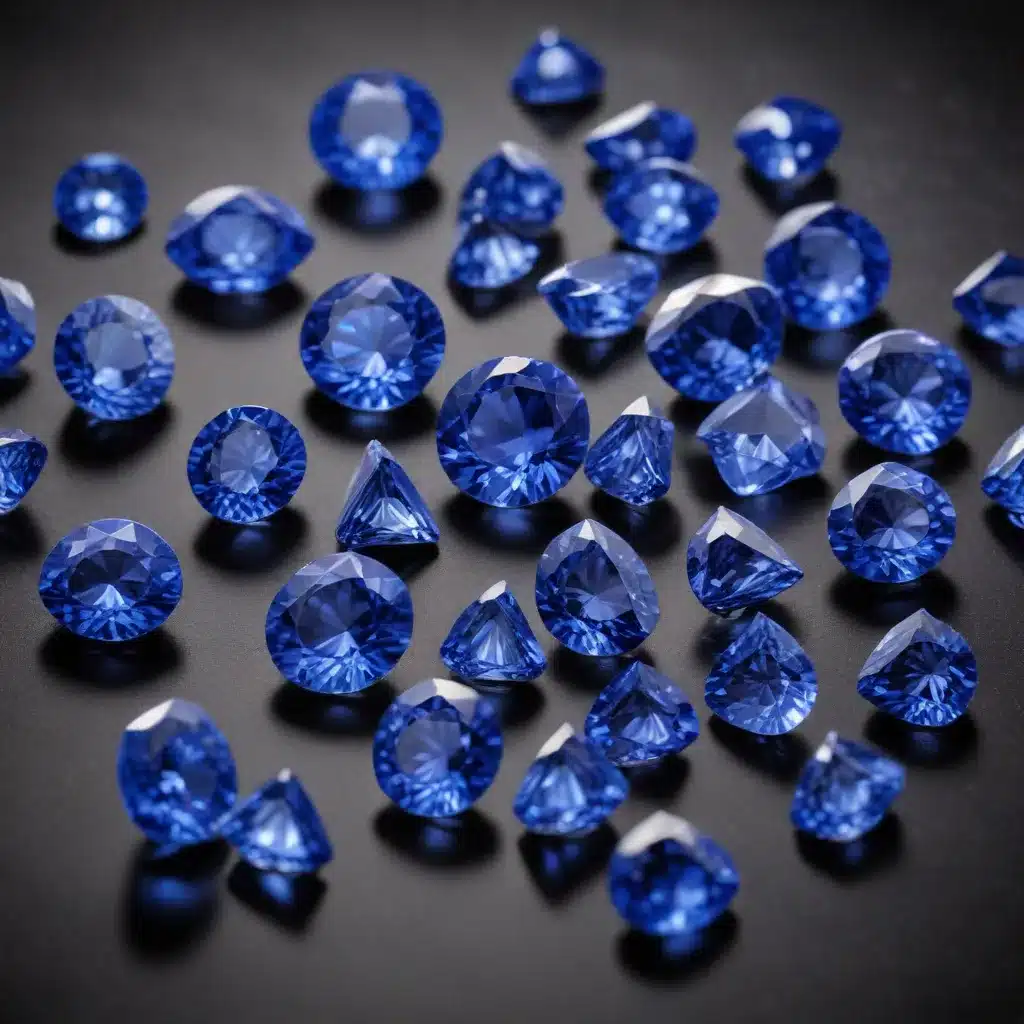

For centuries, gemstones have captivated the human imagination with their unparalleled beauty and mystique. From the deep azure hues of sapphires to the vivid crimson of rubies, these natural wonders have long been prized for their rarity and splendor. However, the advent of synthetic gemstone technology has revolutionized the jewelry industry, offering a sustainable and affordable alternative to their earth-mined counterparts.

The History of Synthetic Sapphire Production

The quest to recreate the allure of natural gemstones has been a captivating pursuit for scientists and artisans alike. In the late 19th century, French chemist Edmond Frémy and his assistant Charles Feil made a breakthrough in the field of synthetic gemstone production. After years of experimentation, they succeeded in growing the first ruby crystals in a laboratory setting, laying the foundation for the modern synthetic gemstone industry.

Building upon Frémy’s work, Auguste Verneuil, a young protégé, developed the “flame fusion” process, which allowed for the production of larger, higher-quality synthetic rubies and sapphires. Verneuil’s innovative technique, which involved carefully controlling the temperature and chemical composition of the growing environment, paved the way for the mass production of these stunning gems.

The significance of these early advancements cannot be overstated. Synthetic sapphires not only provided a more accessible and affordable alternative to their natural counterparts but also opened up new avenues for technological innovation. The unique properties of these lab-grown gems, such as their exceptional hardness and optical properties, soon found applications beyond the jewelry industry, revolutionizing fields like optics and precision instrumentation.

The Science of Synthetic Sapphire Cultivation

At the heart of the synthetic sapphire production process lies an intricate dance between chemistry, physics, and engineering. The flame fusion method pioneered by Verneuil remains a widely used technique, though modern scientists have refined and enhanced the process to achieve even greater levels of precision and quality.

The cultivation of synthetic sapphires begins with the selection of high-purity aluminum oxide (Al2O3), the primary component of natural sapphires. This raw material is then carefully introduced into a specialized chamber, where it is exposed to an intense, controlled heat source, such as a hydrogen-oxygen flame. As the aluminum oxide melts, it forms a molten droplet that is slowly lowered, allowing the material to solidify and crystallize into a pear-shaped boule, or synthetic sapphire crystal.

The chemical composition of the final product is meticulously monitored, with the strategic addition of trace elements like chromium or iron to impart the desired hue. This color-enhancing process is crucial, as it replicates the natural formation of sapphires, which gain their distinctive blue, pink, or yellow tones from the presence of these impurities.

Ensuring quality and consistency is a paramount concern in the synthetic sapphire industry. Stringent controls are in place to maintain precise temperature, pressure, and growth rate throughout the cultivation process, resulting in gems that are virtually flawless and free from the internal irregularities often found in natural stones.

The Artistic Approach to Synthetic Sapphire Design

The journey of a synthetic sapphire does not end with its cultivation; it is further refined through the skilled hands of gem cutters and jewelry designers. These artisans apply their expertise to unlock the true brilliance and beauty of these lab-grown gems.

The cutting and polishing of synthetic sapphires require meticulous attention to detail, as even subtle changes in facet angles and proportions can have a significant impact on the stone’s fire, brilliance, and dispersion. Experienced cutters carefully analyze the unique characteristics of each crystal, tailoring their techniques to maximize the gem’s inherent optical properties.

Alongside these technical considerations, jewelry designers embrace the creative potential of synthetic sapphires, incorporating them into innovative settings and profiles. From sleek, minimalist designs to intricate, vintage-inspired pieces, the versatility of these lab-grown gems allows for boundless design possibilities. The result is a harmonious blend of scientific precision and artistic expression, where the beauty of the stone is elevated by the craftsmanship of the jeweler.

Sustainable Practices in Synthetic Sapphire Production

As the demand for ethical and environmentally conscious jewelry continues to grow, the synthetic gemstone industry has emerged as a shining example of sustainable practices. By cultivating sapphires in a controlled laboratory setting, producers can minimize the environmental impact associated with traditional mining operations, which often involve extensive soil disturbance, water pollution, and energy consumption.

Moreover, the traceability and transparency inherent in synthetic gemstone production ensure that consumers can make informed, responsible choices. Rigorous certification programs and international standards, such as the Kimberley Process for diamonds, provide assurance that these lab-grown gems are free from any association with unethical labor practices or conflict-prone regions.

Synthetic sapphire producers are also embracing the principles of the circular economy, finding innovative ways to reuse and recycle materials throughout the production lifecycle. This commitment to sustainability not only benefits the environment but also enhances the overall value proposition for consumers seeking ethically sourced, high-quality jewelry.

Applications of Synthetic Sapphires Beyond Jewelry

While the jewelry industry has undoubtedly been the primary driver of synthetic sapphire demand, these remarkable gems have found numerous applications in various technological and industrial sectors. Their exceptional hardness, thermal conductivity, and optical properties make them invaluable components in a wide range of specialized products.

In the realm of optics, synthetic sapphires are used to create high-performance lenses and windows for applications ranging from precision telescopes to military equipment. Their ability to withstand extreme temperatures and environmental stresses has also made them indispensable in the production of semiconductor devices, LED lighting, and chemical processing equipment.

Beyond these technological applications, synthetic sapphires have even found a place in the world of haute couture, with designers incorporating them into luxurious accessories and fashion items. This multifaceted utility underscores the versatility and enduring appeal of these remarkable lab-grown gems, positioning them as essential contributors to the ever-evolving landscape of science, technology, and design.

The Future of Synthetic Sapphire Innovation

As the synthetic gemstone industry continues to evolve, the future of synthetic sapphires promises to be both exciting and transformative. Researchers are constantly exploring new crystal growth techniques and material compositions, aiming to push the boundaries of what is possible in terms of size, quality, and color.

Emerging technologies, such as the incorporation of artificial intelligence and machine learning algorithms, are revolutionizing the production process, allowing for even greater precision and consistency in the cultivation of these lab-grown gems. Additionally, the integration of sustainable energy sources and advanced manufacturing methods is further enhancing the environmental credentials of synthetic sapphire production.

As consumer demand for ethical and innovative jewelry continues to rise, the role of synthetic sapphires is poised to become increasingly prominent. These lab-grown gems, with their unparalleled beauty and diverse applications, are set to remain at the forefront of the gemstone industry, captivating the hearts and minds of jewelry enthusiasts, technology innovators, and fashion trendsetters alike.